High-Sensitivity Metal Detector for Frozen Diced Vegetables Safety Solution

This high-sensitivity metal detector for frozen vegetables uses multi-frequency detection technology to accurately identify ferrous, non-ferrous, and stainless steel contaminants, unaffected by product temperature or packaging materials. The digital food metal detector system employs cutting-edge detection technology and a robust stainless steel construction, maintaining accurate operation even in cold, humid, or frosty environments. Its anti-condensation function, waterproof construction, and high-sensitivity sensor make it ideal for continuous operation in frozen vegetable processing plants. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us for a quote.

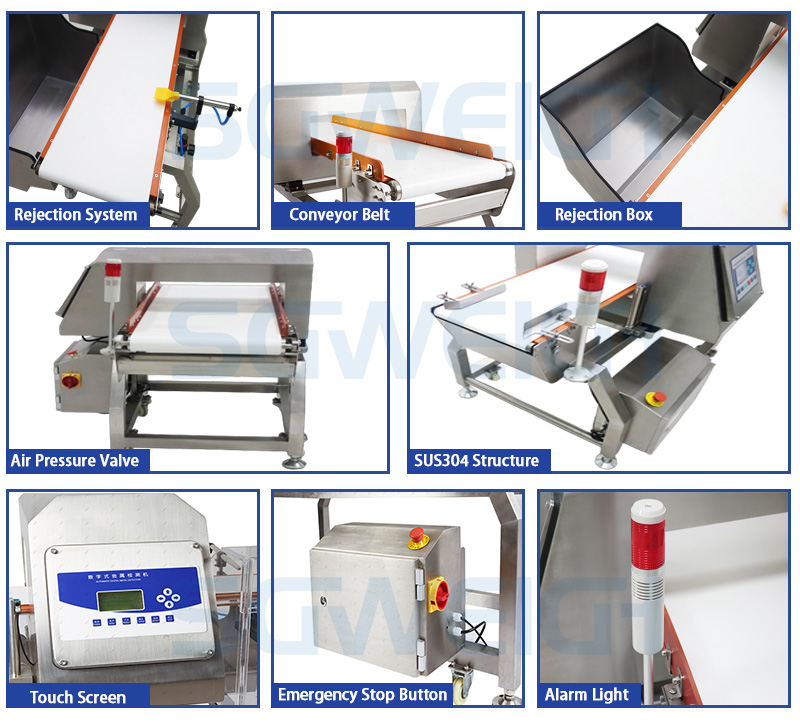

Automatic food metal detector conveyor photos

Power: AC220V±10% 50-60Hz

Material: 304 stainless steel body

Operating Mode: Automatic & Manual

Channel Size: 500mm*250mm (customizable)

Belt Speed: 28m/min (customizable)

Sensitivity: Iron ball diameter (φmm) 0.6-0.8; 304 stainless steel diameter (φmm) 1.2; Copper, aluminum, lead, and other non-metallic materials (φmm) 1.2

Dimensions: 1700*980*1100 (customizable)

Ground Height: 750±50mm (customizable)

Operating Environment: Temperature -18~50°C

1. High sensitivity for detecting ferrous, non-ferrous, and stainless steel metals

2. Freeze-proof and waterproof design, suitable for frozen food environments

3. Automatic rejection mechanism ensures continuous, contamination-free production

4. Intuitive touchscreen control for easy setup and data management

5. Complies with international food safety and quality standards

6. Reliable reliability, hygiene, and compliance

Perfect For:

1. Frozen diced vegetable production lines

2. Ready-to-eat and frozen meal packaging plants

3. Vegetable processing and sorting facilities

High-Sensitivity Metal Detector for Frozen Diced Vegetables Safety Solution

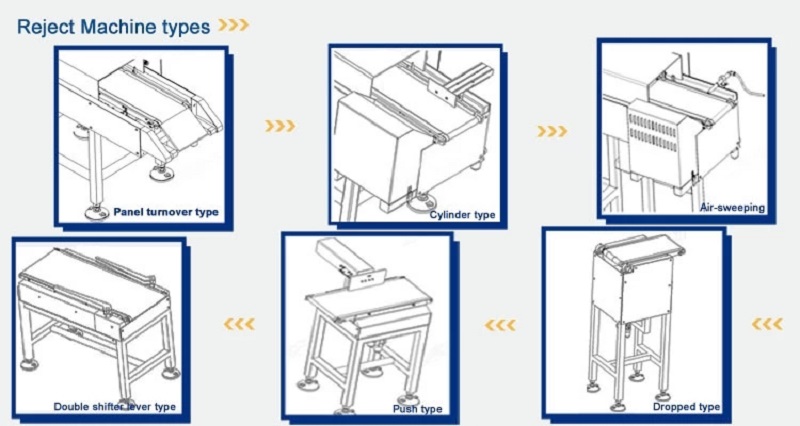

The high-sensitivity metal detector for frozen vegetables shown may not meet your requirements. Our company can provide customized digital metal detector for food equipment according to the user's production and application environment requirements, which can be perfectly integrated with the existing production line.

High-Sensitivity Metal Detector for Frozen Diced Vegetables Safety Solution

Packaging:

1: Lubricate the drive unit

2: Divide the machine into modules

3: Wrap the modules with plastic film

4: Pack the modules into cartons

5: Make the shipping mark

If you have any special requirements, we will pack according to your needs.

Pre-sales Service

1. Test with customer engineers to learn how to use the machine.

2. Show product samples and our machine.

3. Test machine video will be sent to the customer, after which the balance will be paid to us.

After-sales Service

1. Manual.

2. Adjustment and setup video.

3. Telecommunications. Or face-to-face online communication is possible.

4. This machine has a one-year warranty and lifetime maintenance. 7/24 online technical support.

Related Products

Stick Jelly Multi-Lane Packing Machine

Industrial Checkweigher with Dual Reject System

Multi-Stage Weight Sorting Machine for Production Lines

Automatic Capsule Metal Detection System

Automatic Capsule Checkweigher for Quality Control

Dynamic Multi-Lane 4-Track Checkweigher

Industrial Box Checkweigher for High-Speed Lines

Wide Range Metal Detector for Bag Packing Line

Precision Nuts Grains Multi-Lane Granule Packing Machine

Online Big Bag Conveyor Metal Detector

Hot Labels: high-sensitivity,metal detector,frozen diced vegetables,safety,solution,quote,manufacturer,price,factory,supplier