Dynamic Blisters Vials Checkweigher for Pharma Box Package Weight Checker

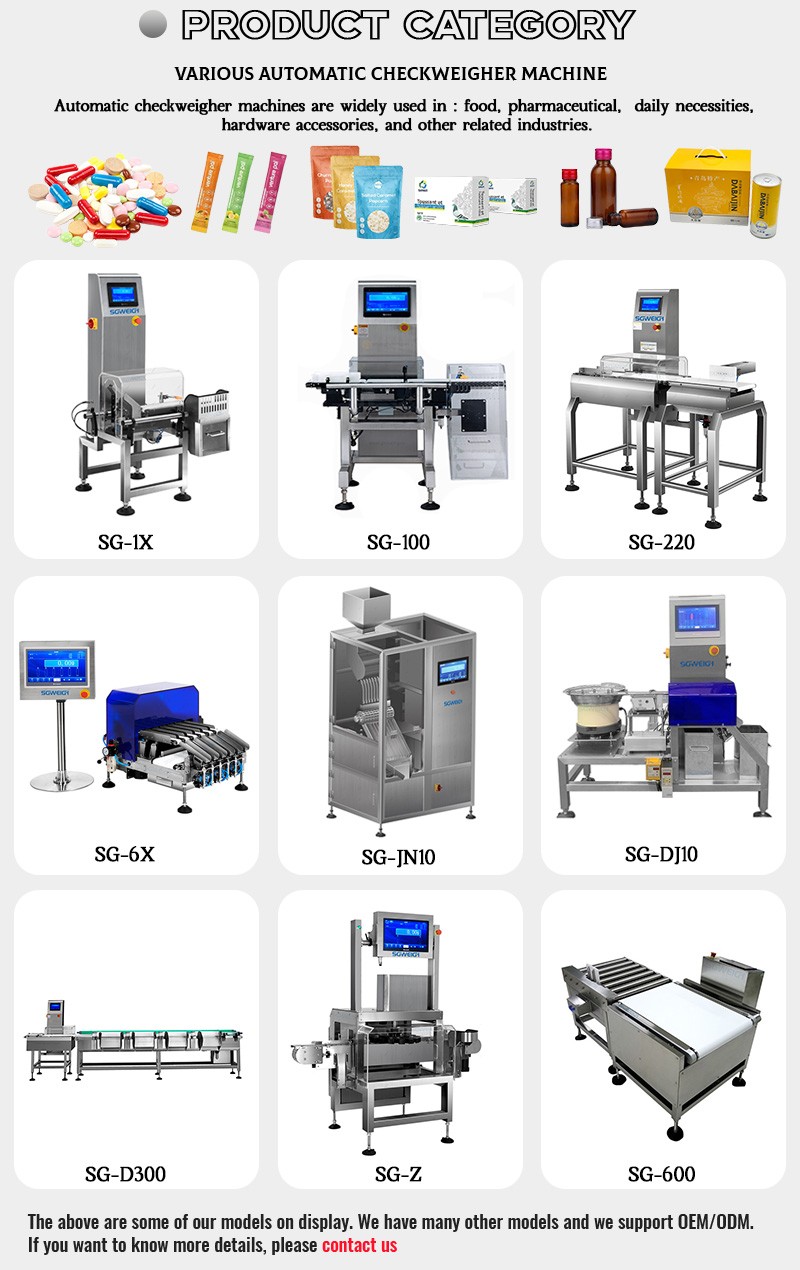

This dynamic blisters vials checkweigher for pharma is designed specifically for pharmaceutical applications, enabling ultra-high precision weight measurement of blister packs and ampoules within packaging boxes. Designed for continuous high-speed operation, pharma box package online weight checker integrates seamlessly into cartoning and end-of-line packaging systems. Its dynamic weighing function allows for accurate measurement without interrupting the production process, automatically rejecting underweight or overweight products. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us for a quote.

Ultra-accurate online checkweigher for pharmaceutical photos

Type SG-100

Weighing Range 2-300g

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±0.05g Depends on product

Division Scale 0.01g

Belt Speed 0- 90 m/min

Max Speed 260 pcs/min

Belt Width 100mm

Machine Weight 70kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Dynamic blisters vials checkweigher for pharma is critical testing equipment on production lines, used in various fields. If the product specifications do not meet your requirements, please contact us with an inquiry or chat with us to meet your customization needs. We can also introduce our factory and machines to you via live stream. Our team will tailor a solution for you.

1. Equipped with a self-developed online dynamic weighing control system and an automatic zero-point tracking system, ensuring reliable detection data. An embedded temperature and noise compensation system guarantees system stability. Years of practical application verification by clients have proven its stability and reliability.

2. A high-precision digital weighing sensor system with high-speed digital filtering and automatic zero-point tracking ensures high speed and high accuracy.

3. Industry-unique dynamic weighing anti-interference correction technology, ensuring both actual weighing accuracy and speed far superior to similar equipment.

4. 100 product presets, freely switchable, user-friendly operating system design, easy to learn and operate, multiple language versions available.

5. Multiple password protections: system parameters and product parameter settings are password protected, allowing only administrators to operate.

6. Easy integration into user production lines, production data reporting function, quick understanding of production status, with data storage and output printing functions.

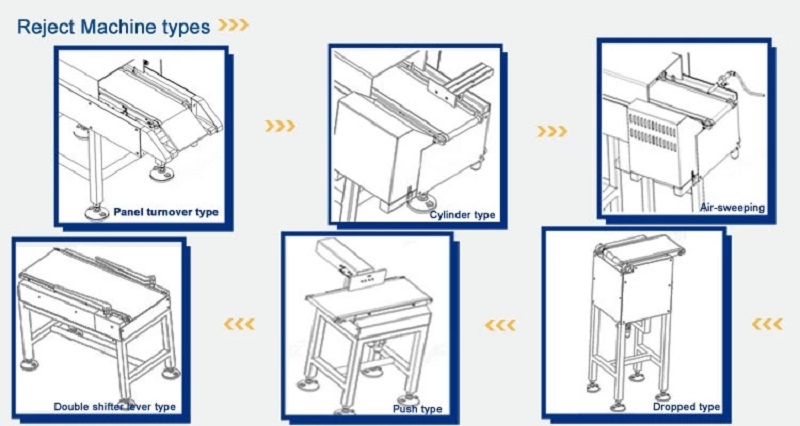

7. Multiple rejection devices: air-blowing type, lever type, roller pusher type, belt pusher type (customizable according to customer needs).

8. The conveyor is made of anodized aluminum alloy, the control box is made of high-grade stainless steel, and the stainless steel frame is brushed, featuring an aesthetically pleasing design and corrosion resistance. The simple mechanical structure facilitates disassembly, cleaning, and maintenance; protection ratings are IP54 and IP65 (customization required).

9. Multiple addable communication protocol ports allow for quick integration into the production system control center, enabling interconnection between devices.

10. Can be integrated with metal detectors, barcode scanners, labelers, inkjet printers, X-ray foreign object detectors, automatic cartoning machines, and automatic box sealing machines.

Dynamic Blisters Vials Checkweigher for Pharma Box Package Weight Checker

Dynamic blisters vials checkweigher for pharma is widely used in industries such as food, pharmaceuticals, beverages, health products, daily chemicals, agricultural products, hardware, toys, electronics, digital products, and printing. For example, they can check whether a bag of products is overweight or underweight; whether a box of products is missing any items; and whether a box of products is missing any accessories.

Dynamic Blisters Vials Checkweigher for Pharma Box Package Weight Checker

Packaging:

1. Lubricate the drive unit

2. Divide the machine into modules

3. Wrap the modules with plastic film

4. Pack the modules into cartons

5. Mark the boxes

If you have any special requirements, we will package them according to your specifications.

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

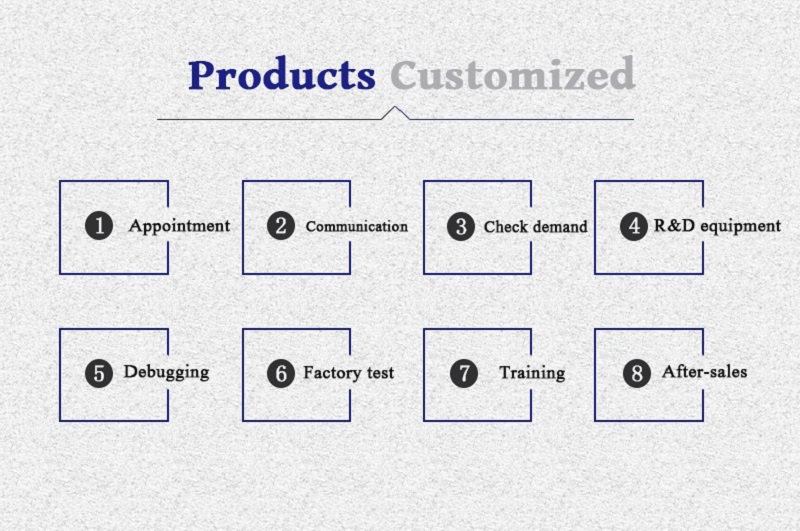

Customization

All our machines can be customized , according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

one year warranty and lifetime maintenance. During the warranty period, accessories damaged by non-human factors will be replaced free of charge; outside the warranty period, accessories will be provided at cost price.

Related Products

Water Multi Lane Sachet Packing Machine

Dynamic Cosmetic Industry Metal Detector

Multi-Lane Checkweigher for Pharmaceutical

Online Weight Checker for Beverage Cans

Capsule Tablet Checkweigher for Small Batch

Combined Metal Detector with Check Weigher System

100% Inline Weight Control Multi-Lane Checkweigher

Food Metal Detector for Beverage Filling Line

Multi-Lane Packaging Machine for Food Sauces

Ultra-High-Speed Checkweigher for Small Box Bottle

Hot Labels: dynamic, blisters, vials, checkweigher for pharma, box, package, weight checker, quote, manufacturer, supplier, factory, price

Boxes of medicine automatic dynamic checkweigher system

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

☂ Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam

filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we

pack the goods in containers and ship them abroad.

Delivery Detail :

☀ Shipped in 25 days after payment

Over the years, Shanghai hard work Industrial Co., Ltd. has been serving customers in the melt industry, after research, exploration, summed up a complete set of product and service support system to provide users with high quality and timely pre-sale, sale, after-sales service:

First, quality assurance

My business department to ensure that the equipment provided to customers is the original production, and factory information accessories complete. In order to maintain the normal operation and maintenance of the contracted equipment, the technical products provided by our department are complete, clear and correct.

Second, quality assurance measures

Warranty period: In the warranty period to provide on-site service.

Hot labels:boxes checkweigher systems,medicine checkweigher,dynamic checkweigher systems,checkweigher,weighing scale,belt weighing machine