Automatic Conveyor Checkweigher for Capsule Tablet High-Precision Weighing Machine

This automatic conveyor checkweigher for capsule tablet provides exceptional speed, accuracy, and reliability for pharmaceutical manufacturing environments. The high-precision capsule tablet checkweigher enables real-time weight monitoring and automatically rejects defective products. Smooth conveying, gentle product handling, and rapid weighing cycles maintain stable production volumes without compromising accuracy. You are welcome to contact us at any time for quotation.

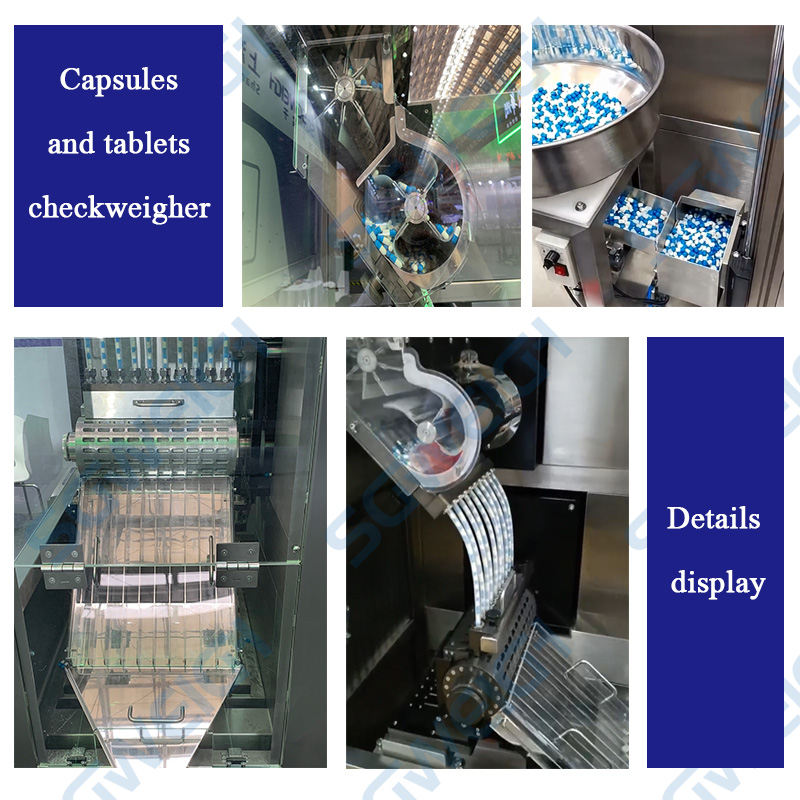

Automatic conveyor checkweigher for capsule tablet photos

Equipment model CM is ±1.0-2000

Design capacity 2000 tablets/minute (120,000 tablets/hour)

Actual capacity >120,000 tablets/hour

Weighing scale 10~2000mg

Resolution 0.1mg

Dynamic accuracy ±1.0mg (actual operation accuracy ±1.0mg, minimum ±1.5mg)

Applicable materials Capsules 000#~5#, conventional tablets

Working voltage AC220V/50Hz

Control voltage DC24V

Rated power 0.6KW (main machine 0.3kw, each single machine 0.15kw)

Working pressure 0.6~0.8 Mpa

Gas consumption 0.1m³/min

Equipment weight 200kg (main machine 60kg, single machine 70kg)

Overall dimensions 740*350*1480mm (main unit width 350mm, stand-alone unit width 190mm)

Automatic Conveyor Checkweigher for Capsule Tablet High-Precision Weighing Machine

1. High-speed weighing sensors for real-time, precise control

2. Automatic calibration algorithms reduce deviations and waste

3. User-friendly touchscreen interface simplifies operation and setup

4. Data logging and connectivity for compliance tracking and batch reporting

5. Compact, modular design for seamless integration into existing systems

6. Consistent weight accuracy across every production cycle

7. Enhanced quality assurance through real-time data visibility

8. Reduced material waste and minimized rework

9. Easily meets international pharmaceutical standards

10. Increased uptime through durable, low-maintenance design

Automatic checkweigher for capsule tablet can detect various types of capsules, including 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#, SA, SB, and regular tablets.

The automatic conveyor checkweigher for capsule tablet shown may not meet your requirements. Our company can provide customized capsule and tablet checkweigher equipment according to the user's production and application environment requirements, perfectly integrated with existing production lines.

Automatic Conveyor Checkweigher for Capsule Tablet High-Precision Weighing Machine

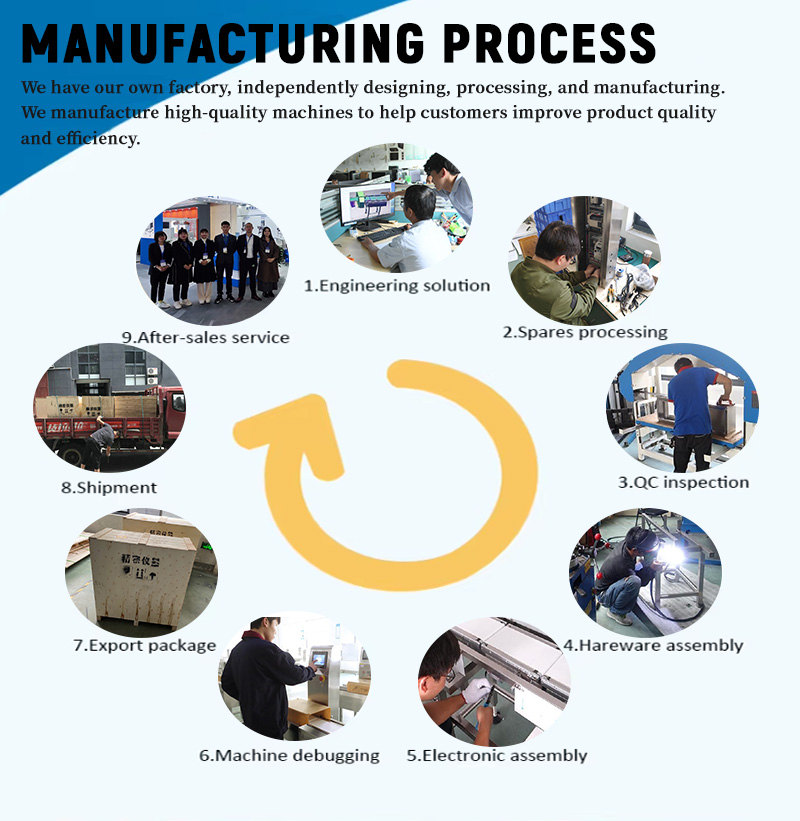

1. Affix safety labels, tighten screws, clean, lubricate, and prevent rust;

2. Unpack into individual units;

3. Wrap tightly with plastic film;

4. Secure in plywood box;

5. Forklift into container.

Suitable for long-distance land and sea transport. For safe loading and unloading to the destination, we recommend full container load (FCL) shipping.

Pre-sales Service:

1. Test with customer engineers to learn how to use the machine.

2. Show product samples and our machines.

3. Test machine video will be sent to the customer; then, the balance will be paid to us.

After-sales service:

1. Manual.

2. Video adjustment and setup.

3. Telecommunications. Or face-to-face online communication is available.

4. This machine comes with a one-year warranty and lifetime repair service. 24/7 online technical support.

Related Products

Multi-Lane Packaging Machine for Disinfectant Powder

Precision Checkweigher for Dry Noodle Packaging

Online Checkweigher for Bottled Tablets Pharma

High-Speed Boxed Cigarettes Checkweigher

High-Accuracy Mini Checkweigher for Capsule Tablet

Dynamic Multi-Stage Weight Sorting System

Bag-Packaged Vermicelli Checkweigher for Food Production

Sound Light Alarm Metal Detector for Industrial

Multi-Lane Powder Packing Machine With Auger Filler

Digital Metal Detector for Capsule Tablet Health Products

Hot Labels: automatic,conveyor,checkweigher,capsule,tablets,high-precision,weighing machine,quote,factory,manufacturer,supplier,price